Genesi

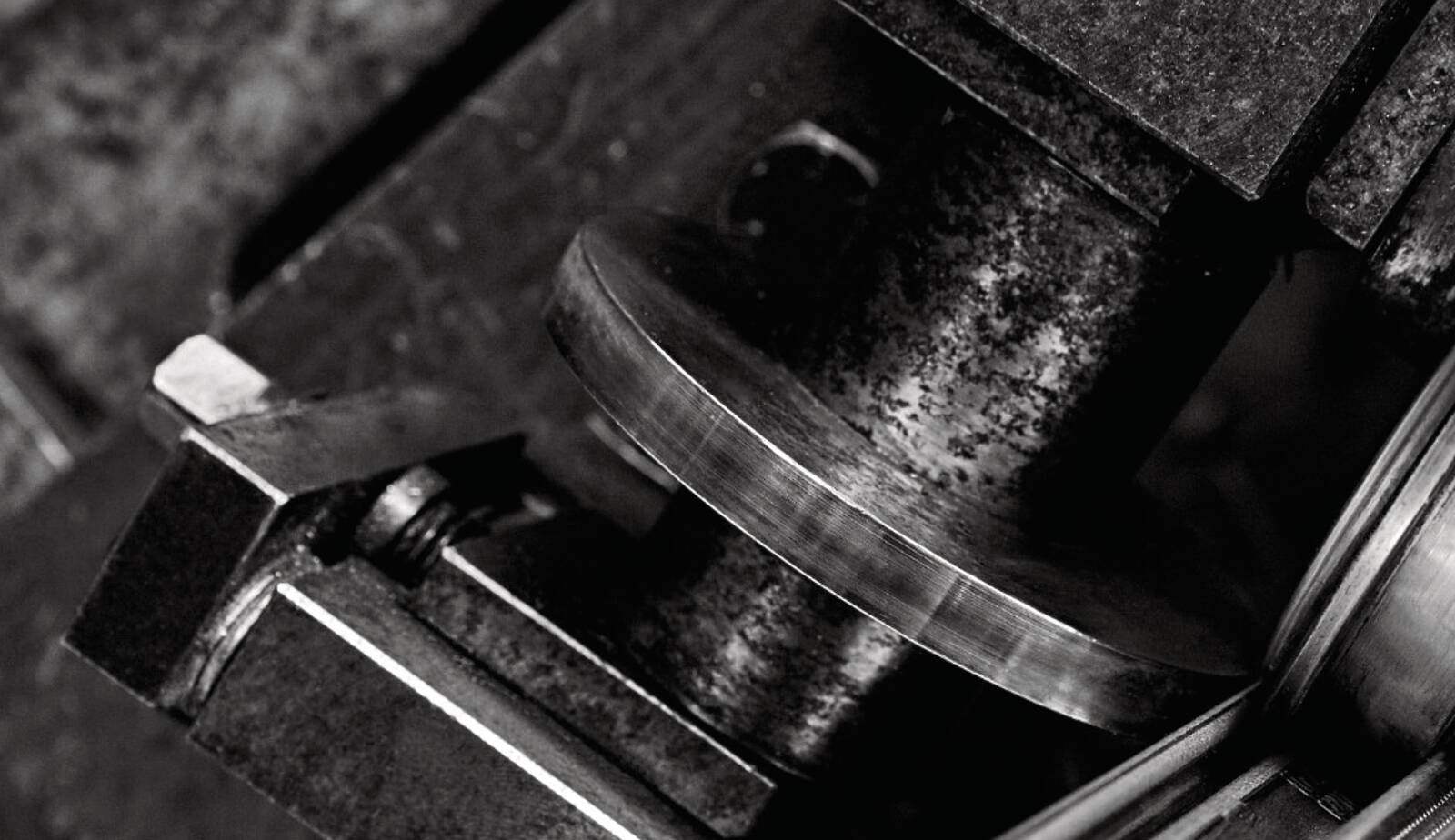

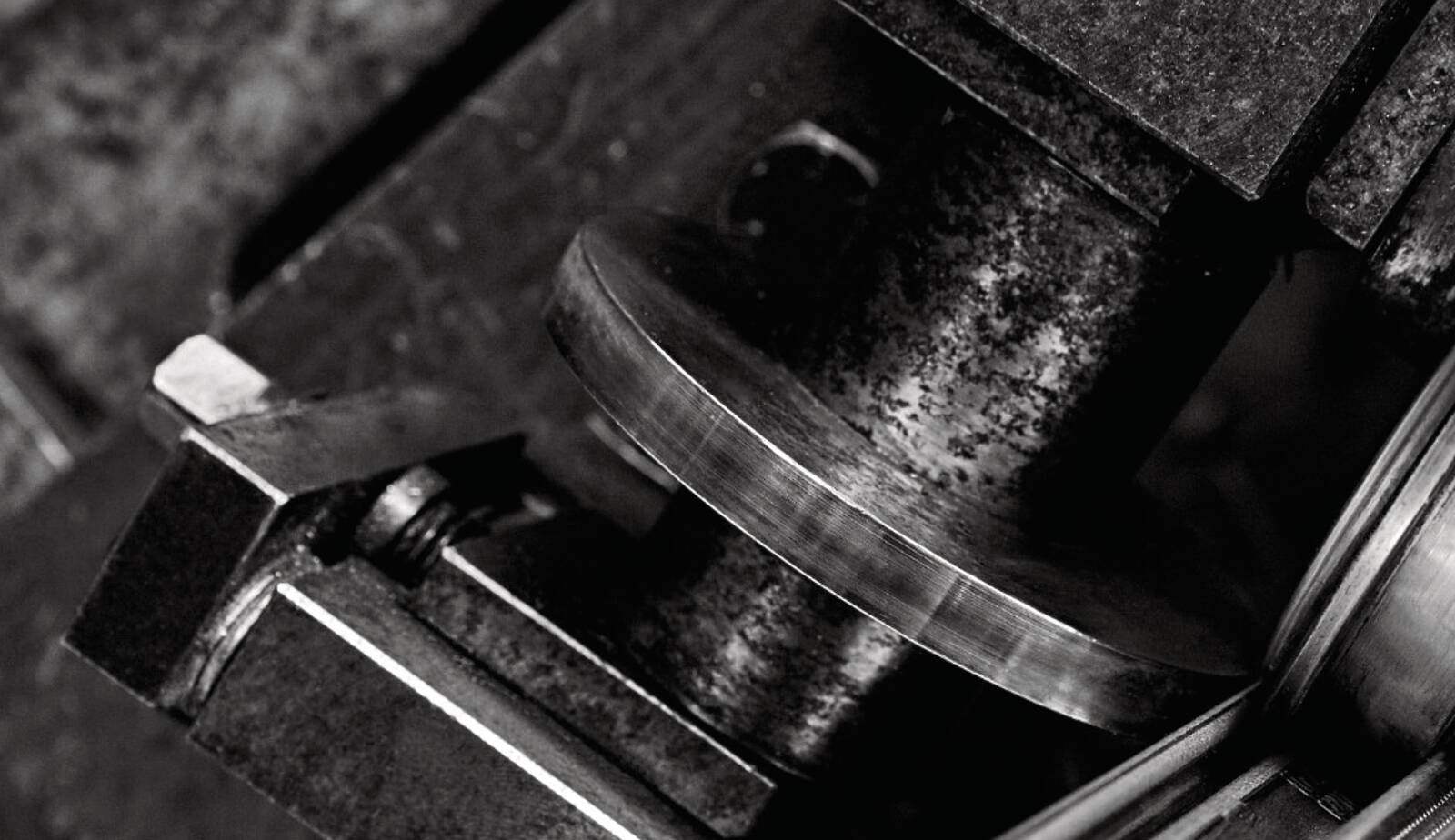

Profile forming

The process of creating metal windows and doors involves cutting strips from large coils of

steel, cor-ten, stainless, or brass, which are inspected for flaws and rejected if any are found.

The strips are then pushed through rolls that progressively shape the metal strip into its final

shape and work-harden the material, increasing its strength.

The two metal halves are combined firmly together with a fiberglass strengthened extrusion,

which is then coated with a high-density polyurethane resin, injected, and set under extreme

pressure. This forms the Thermally Broken element, which significantly reduces conductivity

and creates a slender and efficient line of steel and architectural bronze windows and doors.